Introduction

Most people only see the final product — a finished t-shirt, hoodie, or uniform. But few understand what happens behind the scenes at a clothing factory. The process of turning a creative idea into a wearable garment involves careful planning, skilled craftsmanship, and modern technology.

In this article, we’ll take you on a step-by-step journey through our factory, showing how your designs come to life — from fabric selection to packaging.

Step 1: Fabric Selection and Sourcing

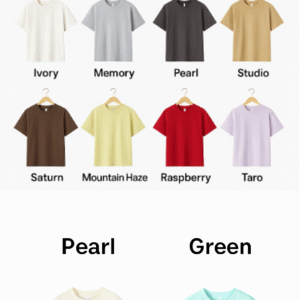

Every great garment begins with the right fabric. The choice of material determines the comfort, durability, and overall look of the final product.

- Cotton: Breathable, soft, and comfortable. Perfect for t-shirts and casual wear.

- Polyester: Durable, wrinkle-resistant, and ideal for sportswear.

- Blends: Cotton-poly blends provide both softness and durability.

- Special Fabrics: Eco-friendly fabrics, moisture-wicking textiles, and stretch materials meet the needs of modern consumers.

As a factory, we work with trusted suppliers to ensure consistent quality. Clients can choose from a wide range of fabrics depending on their project.

Step 2: Pattern Making and Cutting

Once the fabric is chosen, the next step is to create patterns based on the client’s design. Skilled pattern makers prepare templates for each garment size, ensuring that the final clothing fits well.

Using automatic cutting machines, we precisely cut the fabric to reduce waste and maintain consistency across large batches. Accuracy in this step is essential because it affects the final shape and comfort of the garment.

Step 3: Printing, Embroidery, and Customization

This is where creativity comes alive. Depending on the client’s requirements, we use different customization techniques:

- Screen Printing – Best for bold designs and large orders.

- Heat Transfer Printing – Perfect for small batches and detailed designs.

- Embroidery – Adds a premium, textured look to logos and patterns.

- Digital Direct-to-Garment Printing (DTG) – Enables full-color, photo-quality prints.

- Foil Stamping / Puff Printing – Special effects for fashion-forward brands.

Customization is what makes the garment unique. Our factory provides detailed samples for approval before mass production.

Step 4: Sewing and Finishing Touches

After customization, the fabric pieces are stitched together by professional sewing teams. From simple t-shirts to complex jackets, each garment goes through multiple stages of stitching.

We pay attention to details such as hems, seams, and collars to ensure durability and comfort. For special orders, we also add extras like zippers, buttons, or custom labels.

Step 5: Quality Control and Packaging

Before shipping, every product is inspected for quality. Our QC team checks:

- Fabric consistency

- Printing accuracy

- Stitching strength

- Size accuracy

- Overall appearance

Only products that pass inspection are packaged and prepared for shipping. Depending on client requests, we also offer custom packaging, hang tags, and labeling services.

Why Working with a Factory Matters

Choosing the right factory partner is critical for success. Unlike middlemen, we provide direct communication, transparent pricing, and full control over production. This ensures clients receive exactly what they want, whether it’s a small batch of 50 pieces or a large order of 10,000.

Conclusion

The journey from idea to finished garment is complex, but with the right partner, it becomes smooth and reliable. At our clothing factory, we combine modern technology, skilled craftsmanship, and strict quality control to bring your designs to life.

Whether you’re a startup brand, a corporate team, or an individual, we’re here to turn your ideas into reality.